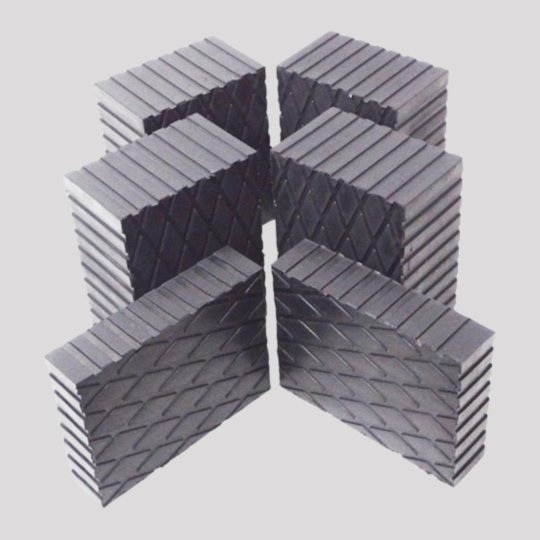

Rubber lift pads are essential tools designed to provide stable and secure support when lifting vehicles, machinery, or heavy equipment. Made from high-quality, durable rubber, these pads are engineered to protect surfaces from damage during lifting and ensure even distribution of weight, reducing the risk of slipping or uneven lifting. Ideal for use in automotive workshops, construction sites, and industrial environments, rubber lift pads help safeguard both the equipment being lifted and the lifting machinery itself. Available in various shapes and sizes, our rubber lift pads are designed for maximum durability and performance, providing a reliable solution for safe, efficient lifting operations.

At Qingdao Todo Rubber, we are committed to delivering exceptional quality, innovation, and customer satisfaction. Here is why we stand out:

1. Expertise and Experience With years of experience in the rubber and silicone manufacturing industry, we bring unmatched technical knowledge and a proven track record of success.

2. Comprehensive Capabilities From custom tooling and design to advanced mixing and production, we offer end-to-end solutions tailored to your needs.

3. High-Quality Standards Our rigorous quality control processes and state-of-the-art testing facilities ensure every product meets or exceeds industry standards.

4. Advanced Equipment We utilize cutting-edge machinery, including large-capacity dispersion mixers, open mixers, and vacuum curing machines, to deliver precision and efficiency.

5. Customization We specialize in creating custom solutions, offering flexibility in materials, colors, and product specifications to meet diverse industry demands.

6. Sustainability We prioritize eco-friendly processes and materials to minimize our environmental impact.

7. Dedicated Customer Support Our team is committed to understanding your unique requirements and providing personalized service from initial inquiry to final delivery.

Choose Qingdao Todo Rubber for reliable, high-quality rubber and silicone solutions that drive your success.

At Qingdao Todo Rubber, we specialize in providing comprehensive rubber and silicone manufacturing solutions. Our expertise spans a wide range of industries, ensuring high-quality, customized products tailored to your specific needs. Our Core Services Rubber and Silicone Moulding: Producing precision-moulded parts in various materials, sizes, and colors for industrial, automotive, medical, and consumer applications. Custom Tooling and Design: Creating tailored tooling solutions for unique product designs and requirements. Rubber Mixing: Advanced mixing capabilities for colored and black rubber, including dispersion and open mixers for optimal results. Vulcanization: High-capacity vulcanizing machines for durable and reliable finished products. Quality Testing: Comprehensive in-house laboratory testing to ensure all products meet stringent quality standards. Key Products Silicone rings, gaskets, and seals. Rubber lift pads, molded parts, and sheets. Custom-engineered components for various industries. Our commitment to innovation, quality, and customer satisfaction makes us a trusted partner for your rubber and silicone needs.

Standardized Pallets: Goods are stacked on heat-treated (ISPM 15) or plastic pallets, optimized for forklift handling. Rigid Corner Protectors: High-impact cardboard corner guards are applied to the full height of the stack. This prevents the straps from cutting into the rubber and maintains the vertical integrity of the pallet.

Price terms

The price is based on FOB, CFR or CIF terms according to Incoterms 2000.

Delivery time

There is no guarantee for the delivery time. The guarantee is only for lead time.

Valid time

The valid time of molding or extrusion profile is 60 days unless there is big changes of raw compound and exchange rate.

Do you have a standard part?

We do not have a standard parts. All of our products are custom made to customer specifications, we may apply for the authorization from customer for the parts same to what you are looking for.

Will I need to invest tooling to produce my product?

If we do not have an existing tooling to meet your requirements, you will have to buy one.

Will you use the tooling for other customers?

No, you will have the 100% rights of the tooling. Please refer to our privacy policy and non disclosure agreement.

How can do I select the raw compound for my application?

With years of experience working with a variety of material, we can help select the material that will best suit your needs while keeping material costs in mind.

Do you use any international standards for the rubber products?

Yes, we use ASTM standards and RAM standards to define the quality of the rubber seal and rubber gaskets.

Can you supply different color material?

Yes, we can produce custom molded rubber and silicone rubber products in a variety of colors.

Package and shipment

All the goods will packed by carton box and loading to the pallet.

If you have any questions or needs about the product, please fill in the following form and we wll contact you as soon as possible.

PHONE: +86 0532 8769 9025

EMAIL: sales@todorubber.com