At Todorubber, quality is not just a department—it is the foundation of our global reputation. With a strategic investment exceeding RMB 200,000 in our specialized laboratory, we ensure that every product leaving our facility meets the rigorous demands of over 20 countries.

We conduct comprehensive testing at every stage: from raw compound validation to final product performance. Our testing protocols adhere to National Standards (GB), International Standards (ISO/ASTM), and specific Customer Proprietary Requirements.

Our laboratory is equipped to verify a wide range of physical and chemical properties:

Mechanical Properties: Hardness (Shore A/D), Tensile Strength, Elongation at Break, and Abrasion Resistance.

Environmental Resilience: Ozone Resistance, Heat Aging, and Corrosive Stress testing.

Thermal Performance: Brittleness Temperature and Low-Temperature Flexibility.

Structural Integrity: Compression Set, Compression Load deflection, and high-precision Dimensional Analysis.

The strength of our lab lies in the expertise behind the equipment.

Decades of Experience: Our engineering team brings over 35 years of specialized experience in rubber and polymer science.

Elite Leadership: Our Chief Engineer is a veteran of the China Northwest Rubber and Plastic Institution, where he led R&D in compound formulation and content design.

Academic Synergy: We maintain a strategic partnership with the Qingdao University of Science & Technology, one of China’s premier institutions for rubber research, allowing us to stay at the forefront of polymer innovation.

To ensure seamless entry into international markets, we collaborate with world-leading inspection bodies such as SGS, API, and TUV. We provide full support for global regulatory requirements, including:

Safety & Environment: RoHS, REACH, and UL certification.

Food & Water Grade: FDA and WPA compliance for silicone and specialized rubber parts.

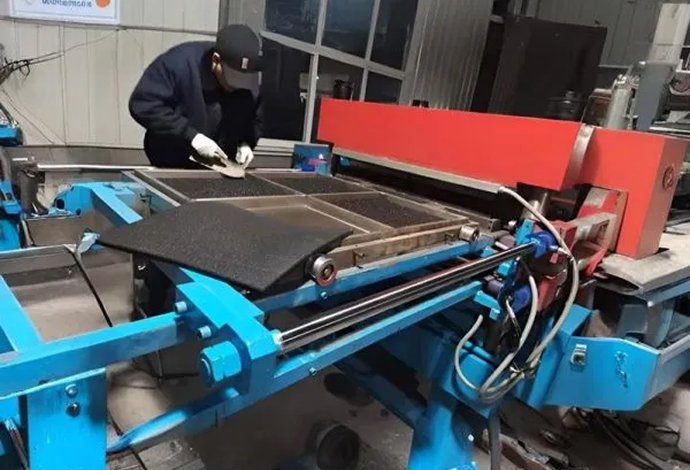

Our facility features state-of-the-art instrumentation to ensure consistent batch-to-batch quality:

Electronic Tensile Testers: For precise measurement of material strength and elasticity.

Ozone Aging Chambers: To simulate years of outdoor exposure in days.

Digital Hardness Testers: Ensuring exact Shore A/D specifications.

High-Precision Rheometers: To analyze the curing characteristics of every rubber batch.

Specific Gravity Balances: For accurate density verification.

PHONE: +86 0532 8769 9025

EMAIL: sales@todorubber.com